The Linen Industry and Art in Barnsley

The Beginning

The growing linen industry in Barnsley provided a source of both artists and their patrons amongst the expanding population in the late 18th and the 19th centuries. William Wilson, a Cheshire Quaker, arrived in Barnsley in 1744. He set up his business producing linen yarn and sent it to be woven across the Pennines in Mottram. From this small beginning, linen production became the main occupation in Barnsley. Wilson’s nephew Joseph Beckett brought weavers from Cheshire and Lancashire to settle in Barnsley. They lived in the 40 cottages that he built in an area of Worsborough Common that became known as Beckett Square. They operated looms in a shed adjoining his warehouse there. Beckett was a skilled business man and became known as the father of the Barnsley linen industry. Production expanded slowly until nearby Leeds mastered the power spinning of flax, creating large quantities quickly to supply the Barnsley weavers.

Growth of the Industry

The biggest area of mills was around Townend where a clean supply of water could be guaranteed from the Sough Dyke and its tributaries. The population of Barnsley increased rapidly, rising from about 1,700 to almost 15,000 between 1750 and 1850. Many more cottages were built in haphazard fashion, as newly enclosed land became available. The development of weaving meant that bleach works were created all across Barnsley, for example at Old Mill and Beevor Hall. There were also dye works and a spinning mill. Was it the attraction of work in an expanding industry that prompted the father of the landscape painter Joseph Mellor to move to Barnsley? Around 1820, he left the Carr Green area of Mapplewell, a village three miles to the north-west of Barnsley, to settle in the town. The Mellors certainly worked in the industry and lived in Kingstone Place, an area of weavers’ cottages. Unfortunately by 1850 the expanding population and the growth of industry meant that the water supply had become severely polluted. The bleach crofts had to move out of town to villages such as Cudworth, to find a clean water supply.

Technological Innovation

As the industrial revolution progressed Barnsley was at the forefront of loom design. Around 1829, a Westmorland man, John Bolton, introduced the Jacquard type loom to Barnsley. Joseph Marie Jacquard designed his loom for use by the silk weavers of Lyons in France. It uses punched cards to create a pattern on the woven fabric and is much faster than the older style looms. These needed two workers to operate them when weaving patterns. Bolton moved to Barnsley around 1818 and set up linen production in Kingstone Place. After seeing a Jacquard loom at a mill in Manchester, he set about improving the design. He shared this with other linen producers in Barnsley, always maintaining that he never earned any money from his design. It was Jacquard’s punch card design that allowed Charles Babbage to use the same technology to create his ‘Difference Engine’. This machine was a calculator and led to the development of the complex computers in use today.

The Hand Loom Weavers

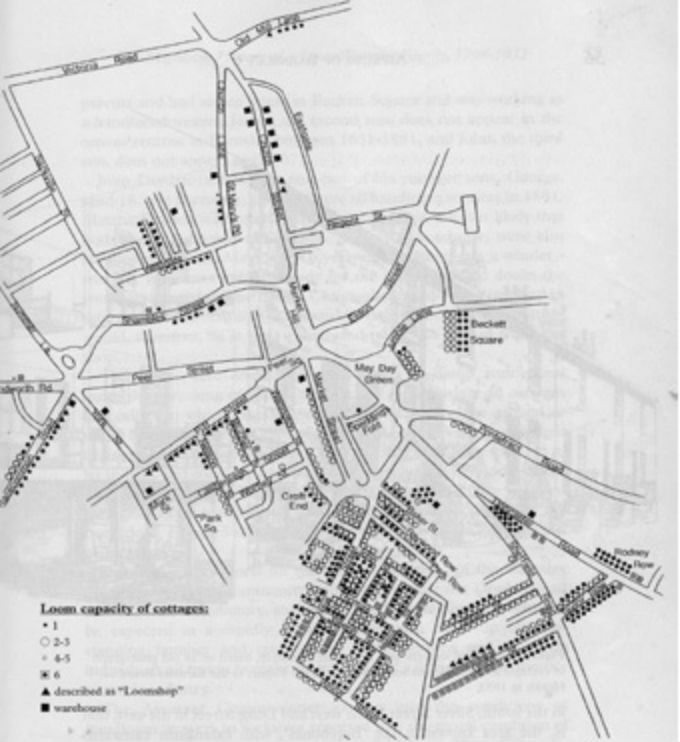

Although a few power looms were introduced in the 1830s, for the first half of the nineteenth century the linen was produced predominantly on handlooms in the weavers’ cottages. Weavers’ cottages were built over a wide area of Barnsley, for example in Churchfield. They were most concentrated in the area bordered by New Street, Wood Street, Silver Street and Duke Street, just to the south of the town centre. This area became known as ‘Barebones’ and was the most povertystricken area of the town. John Wilson, cousin to Joseph Beckett, developed part of this area which became known as Wilson’s Piece.

The cottages had two floors, for living rooms and bedrooms, and a cellar. The looms were installed in cellars. As these were much damper than the upper levels, linen yarn was less likely to break. They had small windows at street level to allow some light in. Although the town was expanding rapidly, the sanitation arrangements were basic. Sometimes cellars had water draining through them, often contaminated with sewage. Working and living conditions were poor with a lack of ventilation and light. The number of looms in a weaving shop varied, but to have four was common. The looms were operated by the master weaver, his journeyman weavers and apprentices, often members of his family. His wife and children could also be involved in the preparation of the yarn. To earn enough money, they worked up to 14 hours a day with only two half-hour breaks for meals. The master weaver dealt with the linen manufacturer, collecting the yarn, delivering the cloth to his warehouse and receiving payment. He had to pay rent for his looms before allocating wages to the journeymen and apprentices.

Weavers And Chartism

There were repeated peaks and troughs in the economic situation in Britain, often caused by conflicts such as the Napoleonic and Crimean Wars and by trade restrictions such as the Corn Laws. During the Crimean War, for example, Russians stopped exporting flax to Britain. The passing of the Corn Laws also affected trade. These laws controlled the importing of cheaper foreign grain to keep corn prices high and protect the profits of large landowners. As a result, some countries were reluctant to buy British linen. Wages were driven down to maintain manufacturers’ profits and some weavers were living in poverty. This led to the development of a strong Chartist element in Barnsley in the first half of the 19th century. The Chartists campaigned for electoral reform so that laws could be passed to improve conditions for the poor. There were weavers’ riots in 1829 and Chartist agitation in 1839, 1842, and 1848 coinciding with the slumps in trade when work was scarce and many weavers were destitute. In June 1838, after a public meeting, the Barnsley Manifesto was drawn up and the details publicised to encourage support for the People’s Charter. Over the next year, unrest increased and eventually Barnsley’s shopkeepers and bankers were threatened. On 2nd August 1839, troops were sent to Barnsley and the Riot Act was read and the situation was defused.

Barnsley was not alone in the poverty experienced amongst its weavers. Between 1837 and 1841 a Royal commission investigated the plight of workers in the linen industry and took testimony from Barnsley men such as John Vallance. They testified how much they earned and what it cost their families to live, showing how their income could not match their expenses.

Quality Products

Despite the harsh working conditions Barnsley became well known for the high quality of the fabrics that it produced. These included linen-cloth, damasks, diapers, drills, ducks, checks and ticks. Jacquard looms were widespread in Barnsley and used to produce the linen damask table linens sought after by the aristocracy. The design process was complex, being first produced on paper before being converted into punched holes on a card. Many cards would be linked together in the correct sequence to produce some of the complex patterns. A single mistake in punching a card could render it useless. Being a jacquard card stamper was a skilled job and in the 1840s Joseph Mellor progressed from linen weaver to jacquard card stamper. Another artist, John Spence Ingall, was a linen damask designer in the 1880s and 1890s and may have produced the paper copies in a format that could be used by the stampers.

Manufacturers, Philanthropists And Patrons Of Art

The Beckett family used some of their fortune to benefit the people of Barnsley. Joseph Beckett’s son John Staniforth Beckett became Deputy Lieutenant for the West Riding of Yorkshire. He built and endowed the Beckett Hospital. John was an art collector and bequeathed paintings to the National Gallery. He also became the patron of Cawthorne-based artist Abel Hold. John commissioned Hold to alter paintings that he had bought. This came to light when Hold’s grandson sold letters from John at auction. Another local family of linen manufacturers was the Harveys. They worked initially from Armitage Yard off Shambles Street before moving the business to Mark Street, into the building that later became Mark Street Central School. They were also philanthropists, giving £1,000 to form the Barnsley Tradesmen’s Benevolent Institution. The eldest brother William participated in the revival of the Mechanics Institute. He left a £1,000 trust to the Institute to allow the creation of a new School of Art and supported the Beckett hospital. Henry was the driving force behind the building of a new public hall. His brother Charles also helped in the management of the hospital. He gave the Public Hall building to the town on condition that a library was established there. A third family was the Coopers. Samuel Cooper built the linen warehouse with a coach house and stables on St Mary’s Place. The building still stands today, in use as a carpet warehouse. Samuel’s son, Samuel Joshua, travelled extensively in Europe with his wife Fanny, amassing a large collection of paintings. In 1912, the Holgate Grammar School moved to a new building in Shaw Lane and he bought the old building in Church Street. He left the building and more than 200 of his paintings to the people of Barnsley. In 1914, the Cooper Gallery opened to the public. The art collection was enlarged when Sir Michael Sadler donated part of his collection of drawings to the Cooper Art Gallery. Sadler was the son of the medical Officer of Health and the son-in-law of Charles Harvey.

Engineering Links To Weaving

In 1850 engineering formed a link with the linen industry when Wilson and Longbottom set up their foundry at Town End, after a few years moving to Foundry Street. Here they made power looms and other plant for use in the textile industry. The company eventually exported all over the world and expanded into the production of many different types of industrial machinery. They were taken over in 1981 but the new company is still operating today at Tankersley near Barnsley.

Decline Of Weaving

More mechanised looms were introduced in the 1860s, powered by steam and fuelled by the locally mined coal. Despite this, the Barnsley industry could not respond to the changing demands of the market and mills gradually closed. In 1851 there were 4,000 handlooms in 800 loomshops and 3,729 people were working in the linen industry. By 1861 this was reduced to 2,538. Robert Darling was the last Barnsley handloom weaver in employment. He died in 1915. By the First World War, less than 800, mostly women, were still employed in the linen industry because remaining tasks needed dexterity not strength. Coal mining was growing to fill the gap and provide jobs for men. Perhaps this decline prompted John Spence Ingall to move permanently to Staithes, near Whitby on the North Yorkshire coast around the turn of the 20th century and to live as an artist. The Barnsley linen industry continued its decline in the 20th century and the last mill closed in 1957. The town has been redeveloped and the weavers’ cottages are gone. The only traces are the linen warehouse on the corner of St Mary’s Place and Churchfield, the remains of some of the bleach works ponds and some remains of the bleach works at Cudworth.

Sources And Bibliography

(1870) Historical Account of Barnsley, Its Industries and Principal Object of interest, Barnsley: printed by T. and C. Lingard. Available from Barnsley M.B.C. Archives and Local Studies

Sketches of Early Barnsley (–1901) No. XXX ‘Introduction of the Jacquard Machine to Barnsley’. Available from Barnsley M.B.C. Archives and Local Studies

277the linen industry and art in barnsley

Alliott, Gerald J. (1999) Linen in Barnsley in Barnsley 1744 to 1957

Bloy, Marjorie ‘A Web of English History: The Barnsley Manifesto – June 1838’ [Online]. Available from http://www.historyhome.co.uk/peel/chartism/ barnchar.htm [Accessed: 26th May 2014]

ECUS – Environmental Consultancy University of Sheffield and Land Use Consultants (2002) ‘Barnsley Borough Landscape Character Assessment’ [Online]. Available from https://www.barnsley.gov.uk/media/Development%20 -%20Planning%20and%20Transportation/Planning%20Policy/LDF/preferred/ underpinning_documents/Landscape%20Character%20Assessment.pdf [Accessed: 6th June 2014]

Essinger, J. (2004) Jacquard’s Web. Oxford: Oxford University Press

Goodchild, J. (1983) Golden Threads: The Barnsley Linen Industry in the Eighteenth and Nineteenth Centuries, Wakefield: Wakefield Historical Publications

Jones, M. (2000) ‘Destination Barnsley: The Migration History of a Linen Weaving, 1798–1932’. In Elliott, B. (ed.) Aspects of Barnsley 6, Trowbridge: Wharncliffe Books

Kaijage, Fred J. (1975) Labouring Barnsley, 1816-1856 : a social and economic history. PhD thesis, University of Warwick.

Keyser, S. (1840) ‘The Sessional Papers of the House of Lords, in the Session 1840, (3 & 4V ictoriae) Arranged inV olumesV ol. XXXVIL’ [Online] Available from http:// books.google.co.uk/books?id=9xFcAAAAQAAJ&pg;=PA480&lpg;=PA480& dq=john+Vallance++weaver++Barnsley+yorkshire&source;=bl&ots;=3e-1SQ L5fx&sig;=p4V3pa1kqsDzlaO4qmPImU2zmlU&hl;=en&sa;=X&ei;=x8N4U6_ xJqOc0AWSioDAAg&ved;=0CEIQ6AEwAw#v=onepage&q;=john%20 Vallance%20%20weaver%20%20Barnsley%20yorkshire&f;=false [Accessed: 18th May 2014]

(1950) ‘Wilson and Longbottom Centenary Dinner’ from The Textile Weekly, 33 Blackfriars Street Manchester

(1950) ‘Yorkshire Loom Makers’ Centenary Celebration’ from Fibres Volume XI November

© Maureen Wilkinson for Barnsley Art on Your Doorstep 2014

Jacquard card making

Weavers Cottages

Taylors Linen Mill

Linen Map

Stairfoot Station Heritage Park

Copyright © Stairfoot Station 2023 All right reserved.

Designed by Bits and Pieces Computers