Barnsley Glass Industry

Rylands & Codd

First patented in 1872 by Hiram Codd (an engineer and soda water bottler), the Codd bottle in its various forms became the vessel of choice for carbonated drinks, a position it held for 60 years. This ‘bottle with a marble’ was made under licence by a host of companies, the most important being Rylands of Stairfoot, at the Hope Glass Works.

Rylands first appeared at Stairfoot in 1867 when Ben Rylands a partner in the South Yorkshire Glass Company at Swinton-looked to establish his own glass-making business in Barnsley. A factory was built alongside the canal at Stanley Road, producing glass jars and corked bottles.

In 1873 Ben Rylands met Hiram Codd and the two collaborated on experiments with Codd’s patented ‘globe stoppered’ mineral water bottle with the aim of perfecting the method of manufacture. Codd has already granted about 20 licences to various bottle manufactures when in April 1874 he granted a licence to Rylands on condition that Rylands buy marbles and seals from Codd, use Codd’s patented groove making tool, and sell only licenced bottling to companies. Glassware from this period is marked ‘B Rylands Bottle Works near Barnsley.

By May 1877 Codd had issued more than 400 ‘bottle usage’ licences to drinks bottling companies and it was at this time that Ben Rylands took him into partnership at the Stairfoot works ‘to further the invention’. Codd held 20 percent stake in the business, which was renamed Rylands & Codd.

Demand for Codd bottles soon exceeded the capacity of the original works. As a temporary measure, capacity was leased from the Dearne & Dove glassworks in Wombwell, while s more permanent (and much larger) site as acquired between Grange Lane and Oaks Lane, with access to the canal, the road network, and the railway. The site grew steadily of the next two decades. Both of Rylands factories operated under the name of ‘Hope Glassworks’, producing food storage jars, mouth-blown (corked) bottles, and the new Codd bottle.

After the death of Ben Rylands in 1881, control of the business passed to his son Dan Rylands and Codd. The relationship was strained from the start. Dan was made to pay a premium renewal of the partnership, and agreed to rename the company Codd & Rylands.

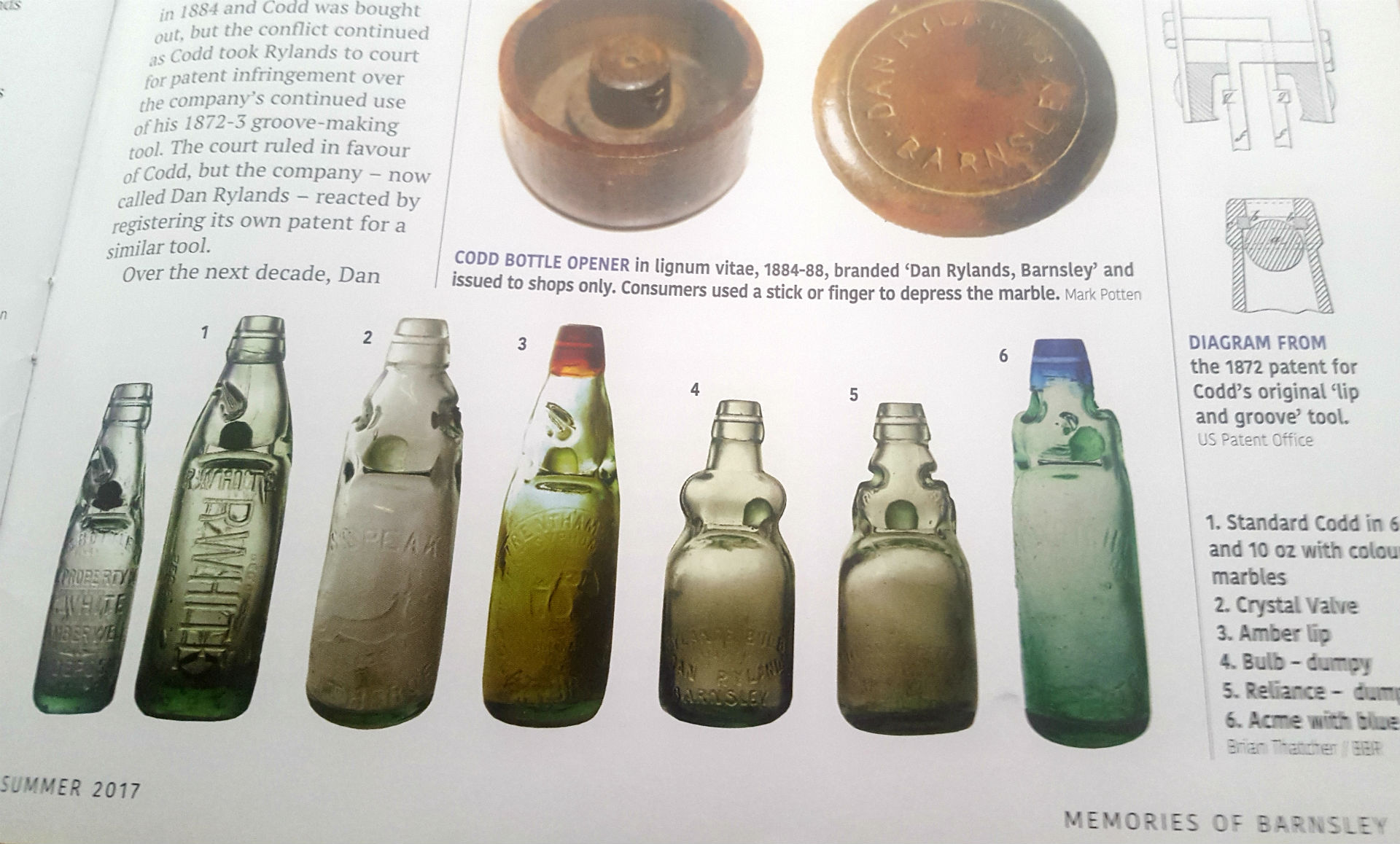

Despite the tension, the partners cooperated on the development of a pressure release valve in the neck of the Codd bottle, jointly registered in 1882 as the Crystal valve patent, but matters came to a head in the following year when Dan Rylands made further improvements to the valve, an action seen by Codd as unwelcome interference in the ‘innovation’ side of the business. By mutual agreement, the partnership was dissolved in 1884 as Codd was bought out, but the conflict continued as Codd took Rylands to court for patent infringement over the company’s continued use of his 1872-3 groove making tool. The court ruled in favour of Codd, but the company- now called Dan Rylands- reacted by registering its own patent for a similar tool.

Over the next decade, Dan Rylands became to owner of more than 90 British and foreign patents relating to the glass-making industry, covering everything from gas production to kilns and bottles, including a string of patents for variants of the standard Codd bottle:-

- The Crystal Valve patent (gas release button).

- The Safe Groove patents (made with Rylands alternative groove tool).

- The Reliance patent (revised double pouring pinch).

- The Empress patent (the sloping cross-pinch).

- The Bulb closure patent (blown bulbs instead of pouring pinches).

- The Coloured lip patent of 1891 (for identification, anti-theft).

- The Acme patent (easier to wash).

The game of marbles was popular with the children. They would often break open the Codd bottles to release the marble an unwelcome cost to bottling companies who relied on bottles being intact. The bottlers’ loss was of course Rylands again.

The Hope Works was now the largest producer of Codd bottles in Europe, with its own gasometers, warehouse, grinding room (for marbles), mould and pattern shops, wire spinning shed, box factory, offices, engineering shops and engine house with a workforce of over 1000 people, for the company supplied the entire UK and exported across the British Empire… but there was trouble brewing on the shop floor.

A new type of furnace- the Siemens furnace- could produce molten glass continuously, but needed to burn gas for 24 hours a day. Dan Rylands wanted to make efficient use of this furnace by changing from the existing 2 x 10 hour shift pattern to 3 x 7 hour shift pattern. The glass workers’ union argued that although the scheme would create more jobs, the reduction in hours would squeeze incomes for existing workers and in September 1886 the workforce went on strike. The union won and the 10 hour shift pattern stayed.

Hiram Codd’s patents expired during the period 1885-88 and Codd himself died in February 1887. Many manufactures in Europe and the U.S.A. now produce their own version of the Codd bottle, although the patents for Rylands variants remained in force. Output at the Hope works increased, aided by innovations such as Dan’s automatic feeder machine, which eliminated the need to employ a ‘gatherer’. He also perfected and patented a storage jar ‘for salmon, meat and fruit’ to add to the existing product range, which included soda syphons.

In 1888-9 the company went public, changing its name to Dan Rylands Limited, with Dan staying chairman and managing director, and taking a reward of the shares. He patented a metal screw cap for use on storage jars. (It failed as a twist cap for wine bottles because of the wines acidity- a problem not solved until the 1960’). About the same time, he developed and patented a new bottle making machine, able to produce around six bottles per minute, but the machine required specially constructed furnaces, for which additional funds had to be raised.

A fire in the box factory led to the losses in 1892 and the position worsened in 1893 due to a strike. Dan Rylands had also invested heavily in the brick making quarry and a coal mine, neither of which were successful. The resulting financial worries and the strain of constant innovation took their toll. Dan’s dangerous state of mental health was highlighted at a meeting of creditors in Barnsley after an audit of his business affairs revealed liabilities of up to £300,000. As bankruptcy loomed, his sympathetic workforce raised £300 to allow him to keep some household goods, but his remaining assets were sold off. Dan resigned his post and moved to London, setting up a mineral water company. He became increasingly eccentric and spent a brief period in an asylum before moving to live with his sister in Battersea, where he took his own life in 1910.

Meanwhile, the Hope Glassworks soldiered on, offering bottles with new treaded vulcanite stopper and the crown cap as they became popular, while maintaining the production of the Codd bottle. From 1895, marbles were sourced from Thomlinsons at the nearby Manor Flint Glassworks (in addition to the existing factories at Kennington and Camberwell). In 1897 the company changed its name to The Rylands Glass and Engineering Company Limited. Bottles made after this time were marked Rylands or The Rylands. To avoid voluntary liquidation in 1905, a financial plan was put together an Mr. Alphonse Wood JP (proprietor of Wood Bros Glassworks, Hoyle Mill) was appointed chairman.

In July 1912 the company played host to King George V and Queen Mary during their visit to Barnsley, the couple being ushered through an arch of the glass battery jars. They were shown a furnace holding 200 tons of metal (glass workers use the word metal to mean molten glass) and saw mouth blown and machine made glassware, including both Cods and ‘corks’. The Queen was particularly interested in Rylands famous fruit jars.

By the 1920’s recession was dragging on Rylands sales, but it chose this time to embark on a major expansion of its Stairfoot works, leaving the company with significant debts. It continued to make the complicated Codd bottle; a process that could not be easily automated. (Machines could produce standard bottles 25 times faster than manual methods). Although Rylands made both internal screw top and crown cap bottles, these were also manufacture in large volumes elsewhere, saturating the market. The company diversified into engineering and packing case manufacture but it was too late, and failure came in 1926. There were attempts to sell Hope works as a going concern but no agreement could be reached. Eventually the factory was stripped and part of the site was taken over in 1929 by Beatson Clark of Rotherham.

As for the Codd bottle, sales declined worldwide as health authorities expressed their concerns about hygiene. Bottlers moved to simpler shapes and by the 1930s the Codd bottle was obsolete. Collectors have identified over 100 variants, some being now quite rare. Curiously, the Codd bottle is still used in two countries: in India for soft drink Banta and in Japan for the soft drink Rumune. The design of these bottles is virtually unchanged since perfected by Hiram Codd and Ben Rylands in 1873.

Variations in Standard Codd Bottles

Rylands Hope Glassworks

Ben Rylands & Hiram Codd

Stairfoot Station Heritage Park

Copyright © Stairfoot Station 2023 All right reserved.

Designed by Bits and Pieces Computers